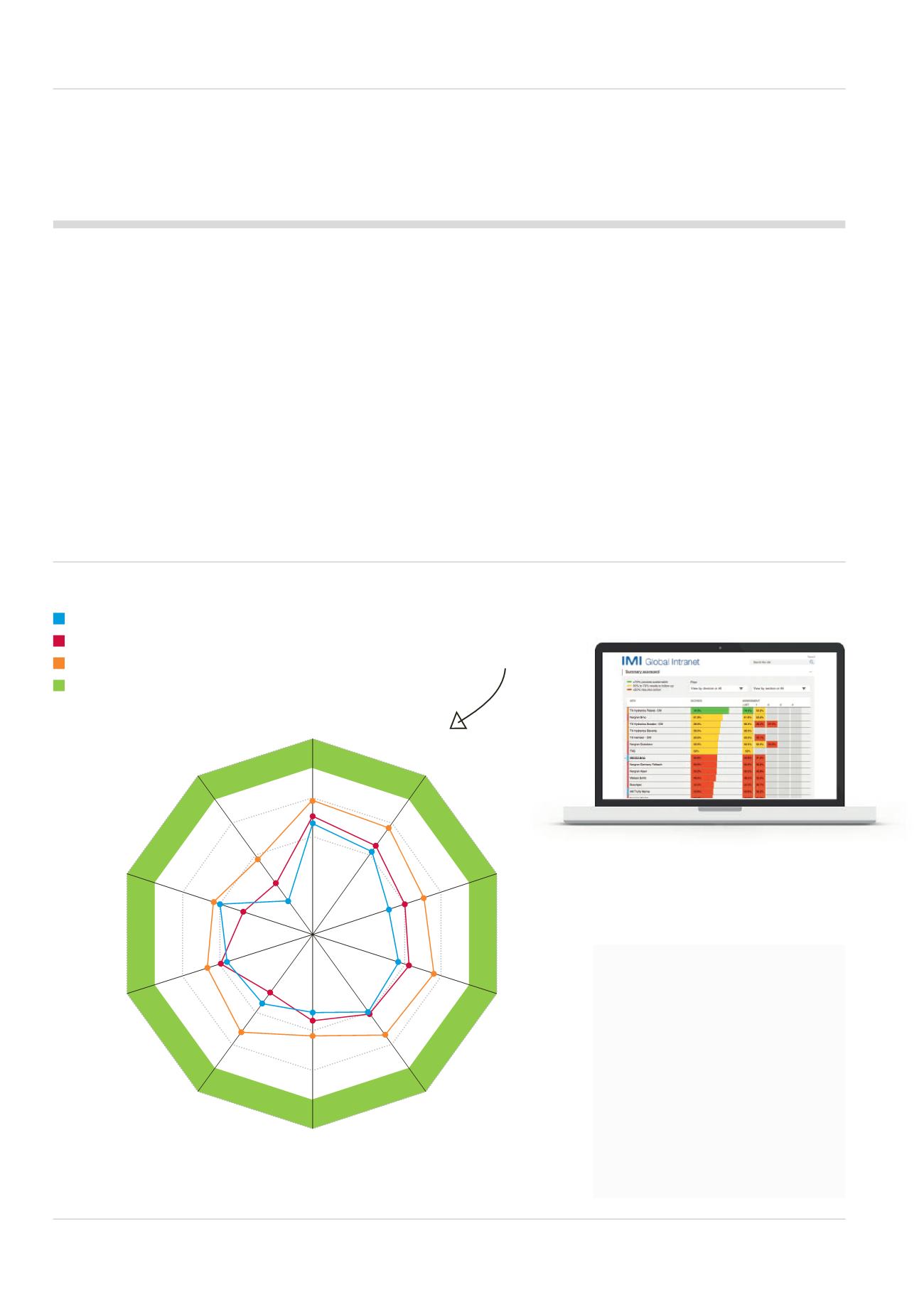

2014 operational snapshot

• Significant excess installed

capacity

• Increased efficiencies will improve

competitiveness

• Supply chain efficiencies will

improve working capital utilisation

• Average score increased

from 31% to 46% and further

ambitious improvement targets

in place for 2015

Chart shows significant

opportunity to

improve

competitiveness

Cultural

Awareness

Visual Management

& Housekeeping

Standardised

Work

Flexible

Operations

Continuous

Improvement

Error

Proofing

Quick

Changeover

Total Productive

Maintenance

Material

Control

Level

Production

The lean assessment score for every IMI site is available

for all employees to view via the lean benchmarking

application on the global intranet. Benchmarking identifies

best practice within IMI and provides visibility of where

to focus improvements and where to go for assistance

to improve performance going forward.

16

IMI plc

Strategy in action

2. Improving operational performance

The benefits of moving towards and achieving best in class operational performance are

very significant. As we improve how our businesses operate we will better utilise capacity,

enhance our competitiveness, reduce working capital and generate cost savings by operating

more efficiently. By doing this, we will also improve services for our customers. Our ambition

is to progressively self-fund our organic growth initiatives using the benefits generated from

our operational improvements. We are on a self-help lean journey, underpinned by the

engagement of management and employees at all levels as we believe this is the best way

to sustain our achievements.

The operational performance of every site in the Group is now being benchmarked every six

months against the ten areas of lean and significant progress has already been achieved. A world-

class operational performance score is 85% or more and at the time of the first benchmark, none of

our facilities came close to achieving this, with the highest score being 57%. Each of our businesses

now have detailed plans in place to achieve world-class performance by 2018.

Second round assessment average lean scores by division

World-class > 85%

IMI Critical Engineering

IMI Precision Engineering

IMI Hydronic Engineering