The benefits of titanium in sea water

applications have been widely

recognised by the offshore Oil & Gas

industry in recent years. Today, principally

in the Norwegian sector of the North Sea,

the number and variety of applications for

titanium and titanium alloys is increasing

at an exponential rate.

The development of unique titanium

valves is part of the industry’s effort

to ensure the highest safety levels for

the new generation of offshore

floating platforms.

The latest IMI CCI titanium valve allows

periodical cycling tests of the platform’s

fire water system, and real time safety

testing for the personnel on board.

Titanium is immune to corrosion and

reduces the installation weight by half

which is an important factor for offshore

floating platforms. The extended service

life and reduced maintenance needs, in

combination with enhanced safety provide

further crucial benefits for the client.

Innovation in new product development

is firmly embedded within IMI CCI

Engineering.

IMI CCI Vienna develops one of the largest titanium

valves ever built

Case studies online

New generation air dryer

Maintenance engineers at New York

City (NYC) Transit had experienced

conditions where moisture in

compressed air caused mechanical

problems on subway cars.

The engineers found that the

standard pressure dryers removed

damaging moisture when they were

first installed on the subway cars, but

performance progressively declined,

especially during hot, humid New York

City summers.

IMI Precision Engineering’s Adsorbent

Media Tube (AMT) dryer uses a patented

technology radically different from

conventional desiccant beads. This

design delivers higher moisture uptake

and faster purging without degrading

the dryer media, improving both

performance and longevity.

NYC Transit replaced the conventional

pressure dryers with AMT test units, and

after 12 months of operation, the test

results showed that the air leaving the

dryers was as dry as when the system

was first installed.

NYC Transit now has a dryer that is

projected to last up to 6 years, or 18,000

service hours, significantly exceeding the

specified two-year maintenance cycle.

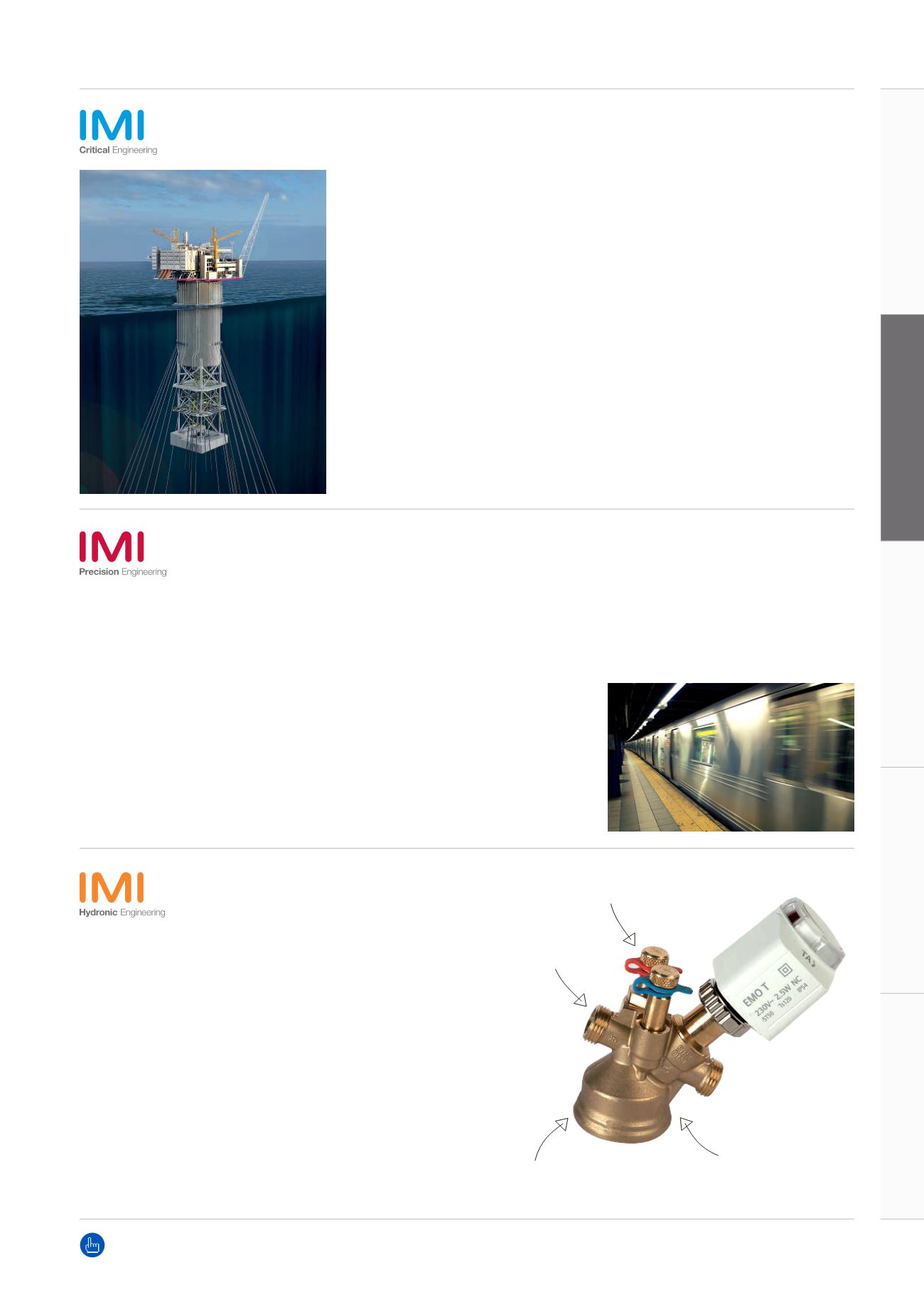

TA-Compact-P: a great new product

developed and introduced in nine months

Kicked off in September 2013 with a cross-functional and

cross-site team and a commitment to an accelerated time line,

development of the TA-Compact-P was driven by customer

requirements and competitor differentiation.

This new range of pressure independent balancing and

control valves required a high-flow capacity, allowing universal

application in cooling and heating systems.

TA-Compact-P was developed to stringent cost, timing

and operational specifications which were all satisfied using

the newly developed project disciplines adopted by the

division. This new range is promising to be one of Hydronic

Engineering’s most exciting product developments in years.

Ametal

®

:

greater longevity

& high resistance

to corrosion

The most compact

valve on the market

Unique

diagnostic

capabilities

Unidirectional

access to all

functions

© Statoil ASA

21

Strategic Review

Performance Review

Corporate Governance

Financial Statements

Introduction

Annual Report and Accounts 2014